Lifting & Rigging

A chain's strength is determined by its weakest link. Rigging is frequently the weak link in crane operations. A load's attachment to a crane can determine whether a lift is successful or results in a tragic accident. Additionally, because such massive and heavy items are lifted, lifting and rigging hazards & its related accidents sometime result in fatalities. Lifting and rigging incidents may lead to tragic events due to a minor error in judgement or a fleeting moment of inattention. There isn't much that can be done to stop a cargo from falling, and there isn't much time for people to get safely out of the way. Expensive cargo and equipment, including the crane itself, could be damaged or destroyed, and a co-worker could be hurt or killed due to Lifting and rigging hazards.

-

DurationHalf Day / 1 Day

-

Training ModeOnline / Classroom

-

Learning PartnerNIST

-

Training TopicLifting & Rigging

-

LevelIntermediate / Advanced

-

LanguageEnglish

-

PrerequisitesNone

-

ScopeIntermediate & Advanced - Theory & Practicals

-

For queries, & Assistance

Introduction:

Any construction job that involves lifting and rigging procedures is crucial since they directly affect both the equipment and worker safety. Every employee at a construction site should have a basic understanding of how to utilise the tools of their trade safely. This lifting and rigging safety training shows how to use various lifting and rigging equipment to ensure safe handling and lifting procedures in detail and gives thorough insight into the lifting and rigging best practices.

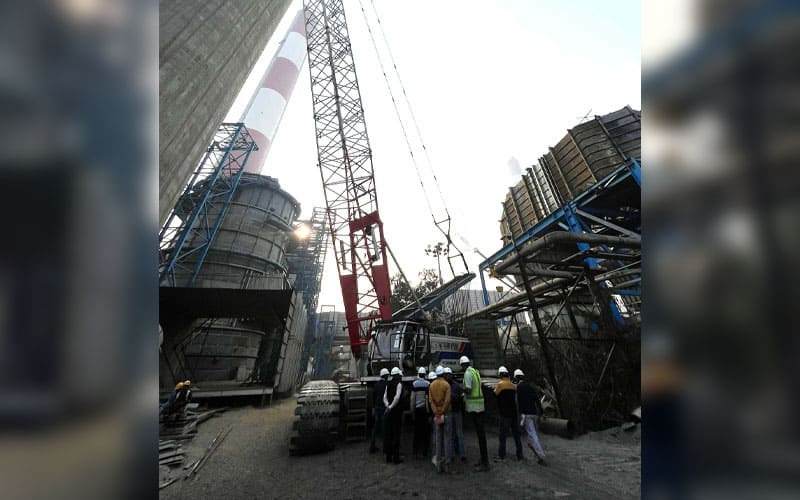

Interactive Session of Lifting & Rigging training

Learning Outcomes of Lifting & Rigging course in India

By the end of the lifting & rigging course a participant would be familiar with:

- Introduction to lifting and rigging

- Legislative / Legal requirements - Lifting

- Roles and responsibilities – Rigger & Signalman

- Classification of crane and its components

- Type of lifting gears / accessories, below the hook equipment and its limitations

- Load characteristics

- Selection of lifting gears / accessories

- Types of hitches & Knots

- Effects of sling angle

- Environmental factors affecting lifting

- Determine the Center of gravity for the load

- Types of hand signals

- Importance of load control

- Identifying hazards of lifting and rigging

- Hazard identification

- Interpretation of Lifting plan and PTW

- Pre-use checks for lifting gears / accessories

- Establish communication between signal and crane operator

- Safe lifting and rigging practices

- Realistic Case Study related to lifting and rigging safety

Who can take the Lifting & Rigging training?

This lifting and rigging certification is ideal for workers who are involved in lifting and rigging operations at construction sites, warehouses, and job sites where heavy or engineered lifts are required to move large objects. Similarly, supervisors and managers with responsibility for lifting and rigging operations can also opt for this lifting and rigging training program to gain insights on lifting and rigging best practises and an understanding of the legal requirements.

Benefits of Lifting & Rigging training

- This lifting and rigging course includes EOT crane operator training, fall protection training, signal person training, rigging inspector training, lifting and rigging risk assessment, etc.,

- The entire lifting team will understand many facets of a crane work & the lifting and rigging hazards and control measures at work site.

- It focuses on the roles and responsibilities of each of the different worker that make up a crane operation safe.

Hello 👋

Welcome back to NIST Global